TM270H drum motor is a heavy roller designed for conveying single heavy items or bulk materials.Its maximum power can reach 5.5kW and its speed can range from 0.62 to 3.37m/s.This kind of drum motor is typically used in:

Motor type:Asychronous, AC, 3 phase

Key words: Belt drive, Oil-filled

Tag:Heavy-duty, Strong torque

AMROLL Drum Motor TM270H-3 *400V/50Hz |

|||||||||

|

Power [kW/hp] |

No.of poles |

Gear stages |

Gear ratio |

Nominal belt speed [m/s] |

Full load torque [Nm] |

Full load belt pull [N] |

Full load current [A] |

Min. face width (L) [mm] |

Min.L Weight [kg] |

|

4.00/5.36 |

4 |

3 |

32.68 |

0.62 |

841.02 |

6230 |

8.80 |

700 |

129 |

|

26.59 |

0.77 |

684.25 |

5069 |

||||||

|

2 |

19.78 |

1.03 |

514.20 |

3809 |

127 |

||||

|

16.17 |

1.26 |

420.34 |

3114 |

||||||

|

15.01 |

1.36 |

390.32 |

2891 |

||||||

|

12.21 |

1.67 |

317.56 |

2352 |

||||||

|

5.50/7.38 |

2 |

3 |

50.99 |

0.81 |

893.00 |

6615 |

10.50 |

700 |

129 |

|

38.52 |

1.07 |

674.64 |

4997 |

||||||

|

32.68 |

1.26 |

572.24 |

4239 |

||||||

|

26.59 |

1.55 |

465.57 |

3449 |

||||||

|

2 |

19.78 |

2.08 |

349.87 |

2592 |

127 |

||||

|

16.17 |

2.54 |

286.01 |

2119 |

||||||

|

15.01 |

2.74 |

265.58 |

1967 |

||||||

|

12.21 |

3.37 |

216.07 |

1601 |

||||||

| At the min. face width (L), the total weight of a drum motor grows approx.5.35kg per 100 mm. | |||||||||

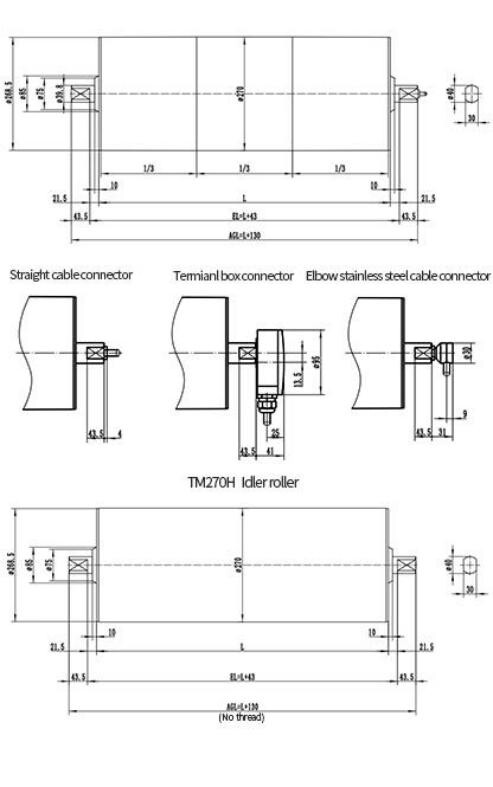

TM270H optional list-drum motor/idler pulley |

||

| Specifications | Drum motor | Idler pulley |

| Shell | ||

| Mild steel crowned | 1 | 1 |

| Mild steel cylindrical | 2 | 2 |

| Stainless steel(std. 304) crowned | 2 | 2 |

| Stainless steel(std. 304) cylindrical | 2 | 2 |

| End housing (front & rear) | ||

| Cast iron | 1 | 1 |

| Cast stainless steel | 2 | 2 |

| Shaft (front & rear) | ||

| Mild steel | 1 | 1 |

| Stainless steel(std. 304) | 2 | 2 |

| Gear box & rear flange | ||

| Cast iron | 1 | 1 |

| Rubber lagging | ||

| Hot vulcanized black smooth rubber lagging | 2 | 2 |

| White and blue rubber lagging in food quality | 2 | 2 |

| Urethane lagging | 2 | 2 |

| Sprockets for modular belting | 2 | 2 |

| V-grooves in the rubber lagging | 3 | 3 |

| Electrical motors | ||

| 3-phase asynchronous motor | 1 | |

| 3*400V/50Hz | 1 | |

| Dual voltage motor | 2 | |

| Most common global voltages at 50 or 60 Hz | 1 | |

| Thermal protection | 1 | |

| Lubricating oil | ||

| No.150 gear oil | 1 | |

| Low temperature oil | 2 | |

| Food grade oil & grease (FDA and USDA) | 2 | |

| Electrical connection | ||

| Straight cable connector | 1 | |

| Elbow stainless steel cable connector | 2 | |

| Terminal box connector | 2 | |

| Oil resistant PVC cable | 1 | |

| LS halogen-free cable | 2 | |

| Screened cable (for VFD and brakes) | 3 | |

| Other options | ||

| Mechanical backstop | 2 | |

| Electromagnetic brake | 2 | |

| Modified for vertical or angled mounting | 3 | |

| Operation with VFD | 2 | |

| Note: 1-fitted as standard 2-optional extras 3-available as limited option but need to confirm with manufacturer | ||