TM80M uses polymer material as the gear material, adopts the planetary transmission structure, fully reduces the operation noise, and has many advantages such as reliable performance, free maintenance, suitable for small installation space and so on. At the same time, due to the special design of the transmission parts, the purchase cost of customers is reduced to the greatest extent, so that this product becomes the ideal driving unit of light load belt conveyor. Over the years, it has been fully recognized and widely used in many fields.This kind of drum motor is typically used in:

Motor type:

Key words:

Tag:

AMROLL Drum Motor TM80M-1*230V/50Hz |

|||||||||

|

Power [kW/hp] |

No.of poles |

Gear stages |

Gear ratio |

Nominal belt speed [m/s] |

Full load torque [Nm] |

Full load belt pull [N] |

Full load current [A] |

Min. face width (L) [mm] |

Min.L Weight [kg] |

|

0.034/0.045 |

4 |

3 |

106.90 |

0.05 |

19.88 |

485 |

0.48 |

280 |

5 |

|

77.70 |

0.08 |

14.92 |

364 |

||||||

|

56.50 |

0.10 |

10.87 |

265 |

||||||

|

2 |

19.40 |

0.30 |

3.73 |

91 |

|||||

|

14.10 |

0.40 |

2.71 |

66 |

||||||

|

0.06/0.08 |

2 |

3 |

106.90 |

0.10 |

17.88 |

436 |

0.57 |

260 |

5 |

|

77.70 |

0.14 |

12.90 |

315 |

||||||

|

56.50 |

0.20 |

9.41 |

230 |

||||||

|

0.085/0.115 |

2 |

3 |

77.70 |

0.15 |

19.40 |

473 |

0.66 |

270 |

5 |

|

56.50 |

0.21 |

14.10 |

344 |

||||||

|

2 |

19.40 |

0.62 |

4.85 |

118 |

|||||

|

14.10 |

0.85 |

3.52 |

86 |

||||||

|

0.11/0.15 |

2 |

3 |

77.70 |

0.15 |

25.90 |

630 |

0.99 |

280 |

5 |

|

56.50 |

0.21 |

18.80 |

459 |

||||||

|

2 |

19.40 |

0.61 |

5.91 |

144 |

|||||

|

14.10 |

0.84 |

4.24 |

103 |

||||||

| At the min. face width (L), the total weight of a drum motor grows approx.0.9kg per 100 mm. | |||||||||

TM80M optional list-drum motor/idler pulley |

||

| Specifications | Drum motor | Idler pulley |

| Shell | ||

| Mild steel crowned | 1 | 1 |

| Mild steel cylindrical | 2 | 2 |

| End housing (front & rear) | ||

| Cast aluminium | 1 | 1 |

| Electrical motors | ||

| 1-phase asynchronous motor | 1 | |

| Voltage1*230V/50Hz | 1 | |

| Most common global voltages at 50 or 60 Hz | 1 | |

| Thermal protection | 1 | |

| Lubricating oil | ||

| NO.32 hydraulic oil | 1 | |

| Low temperature oil | 2 | |

| Electrical connection | ||

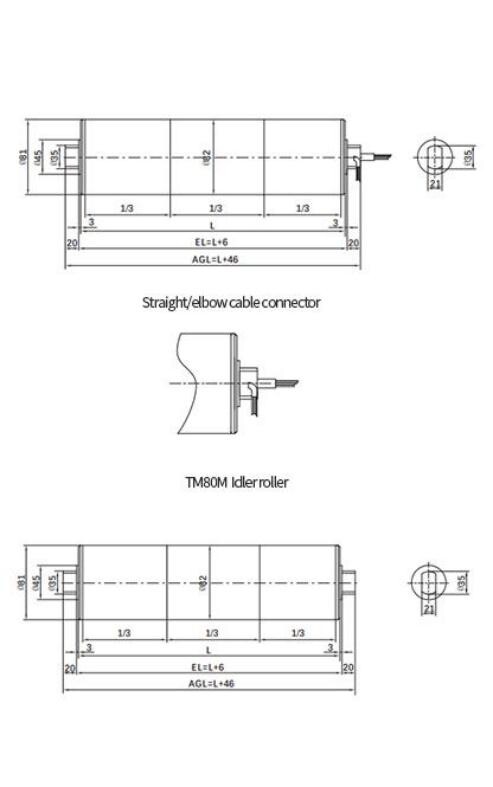

| Straight/elbow cable connector | 1 | |

| Oil resistant PVC cable | 1 | |

| Note:1-fitted as standard 2-optional extras | ||