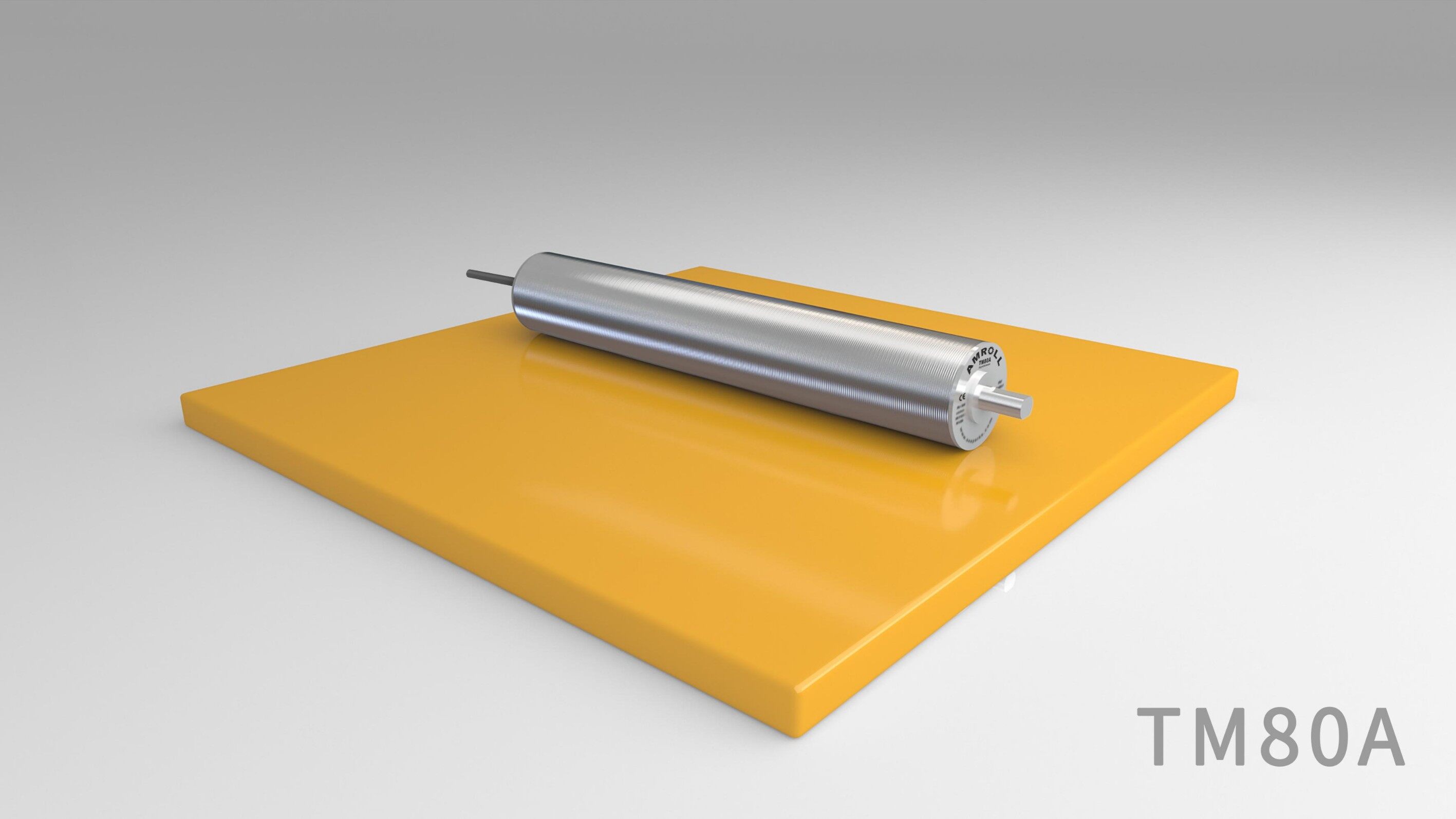

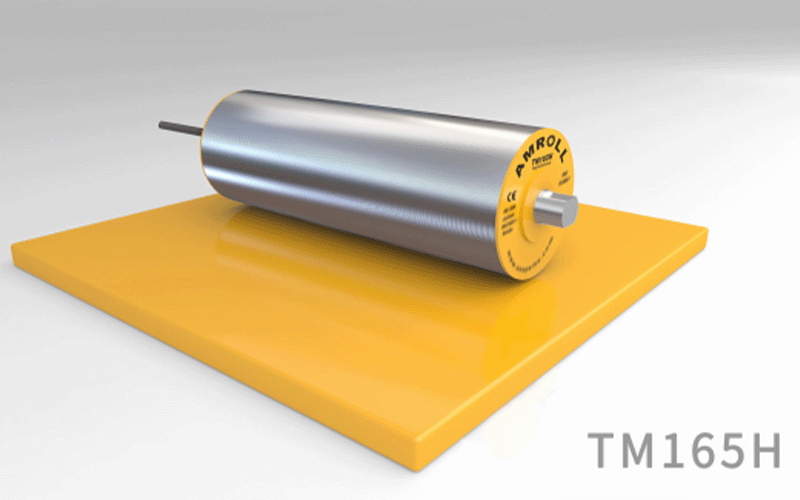

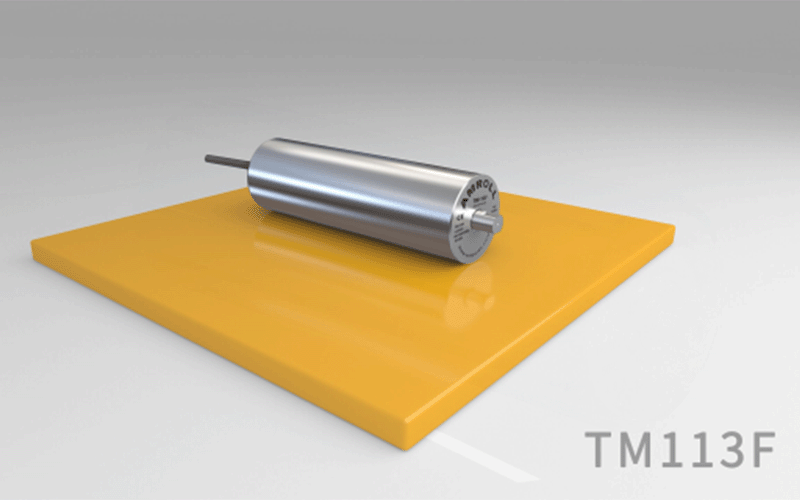

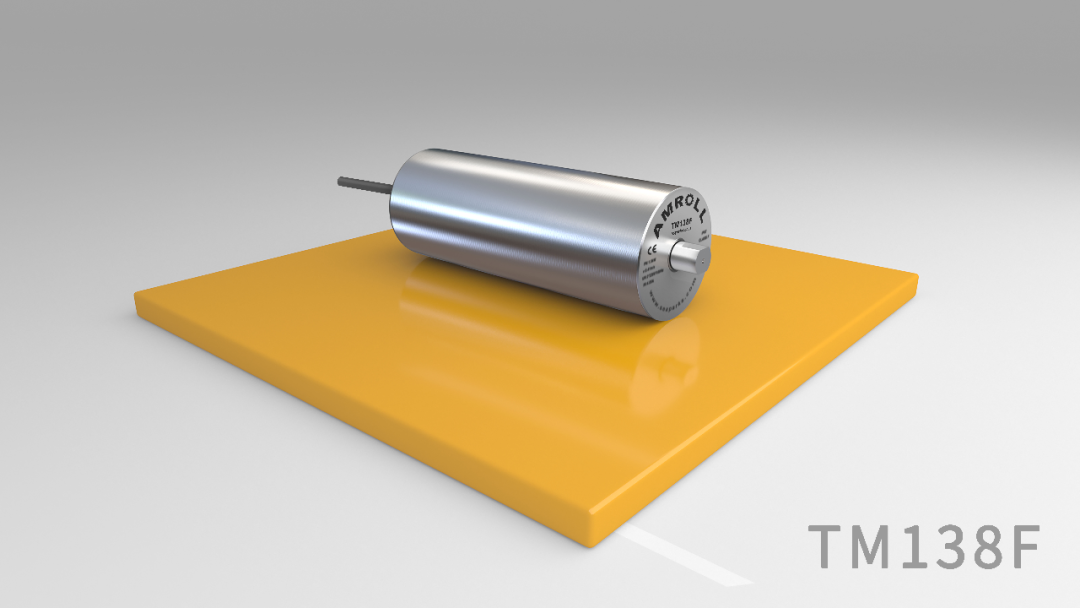

Thank you all for your continuous attention and support for Seaparks drum motors. As a professional manufacturer specializing in core drive components for conveyor systems, we deeply understand the significance of drum motors in various scenarios. Today, we will elaborate on the correct usage methods of drum motors and discuss how to effectively address issues such as belt misalignment and slippage.

In ensuring the stable operation of the drum motor belt, we must comprehensively consider multiple key aspects to effectively prevent slippage issues. Below, we will delve into the strategies for addressing these seven key aspects:

1. **Correct Product Selection:**

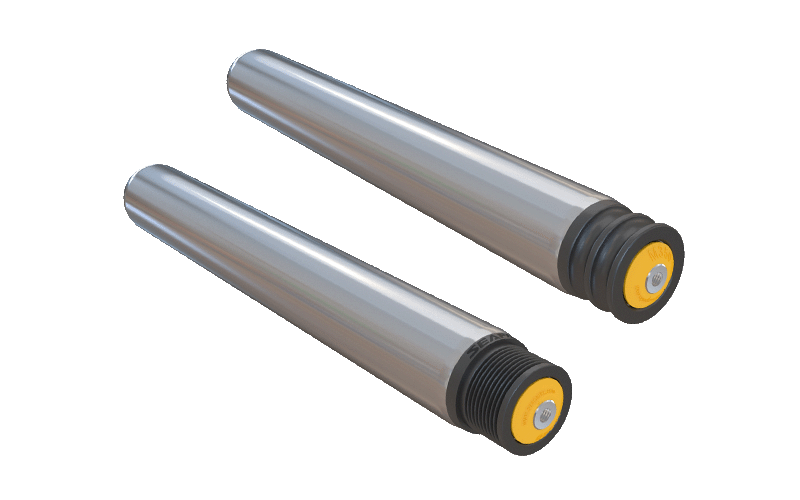

When choosing the appropriate model of drum motor, it's necessary to consider multiple factors to ensure that belt misalignment issues are avoided. Key considerations include:

- Accurate matching of load range: Selecting the right model to ensure that the drum motor can withstand the load without exceeding its capacity, thus avoiding slippage due to overloading.

- Environmental adaptability: Avoiding prolonged operation of the drum motor in environments with oil or water, and timely implementing waterproof and oil-proof measures.

- Matching appropriate dimensions: Choosing a belt thickness that matches the drum motor diameter to prevent misalignment issues caused by mismatched dimensions.

2. **Proper Equipment Installation:**

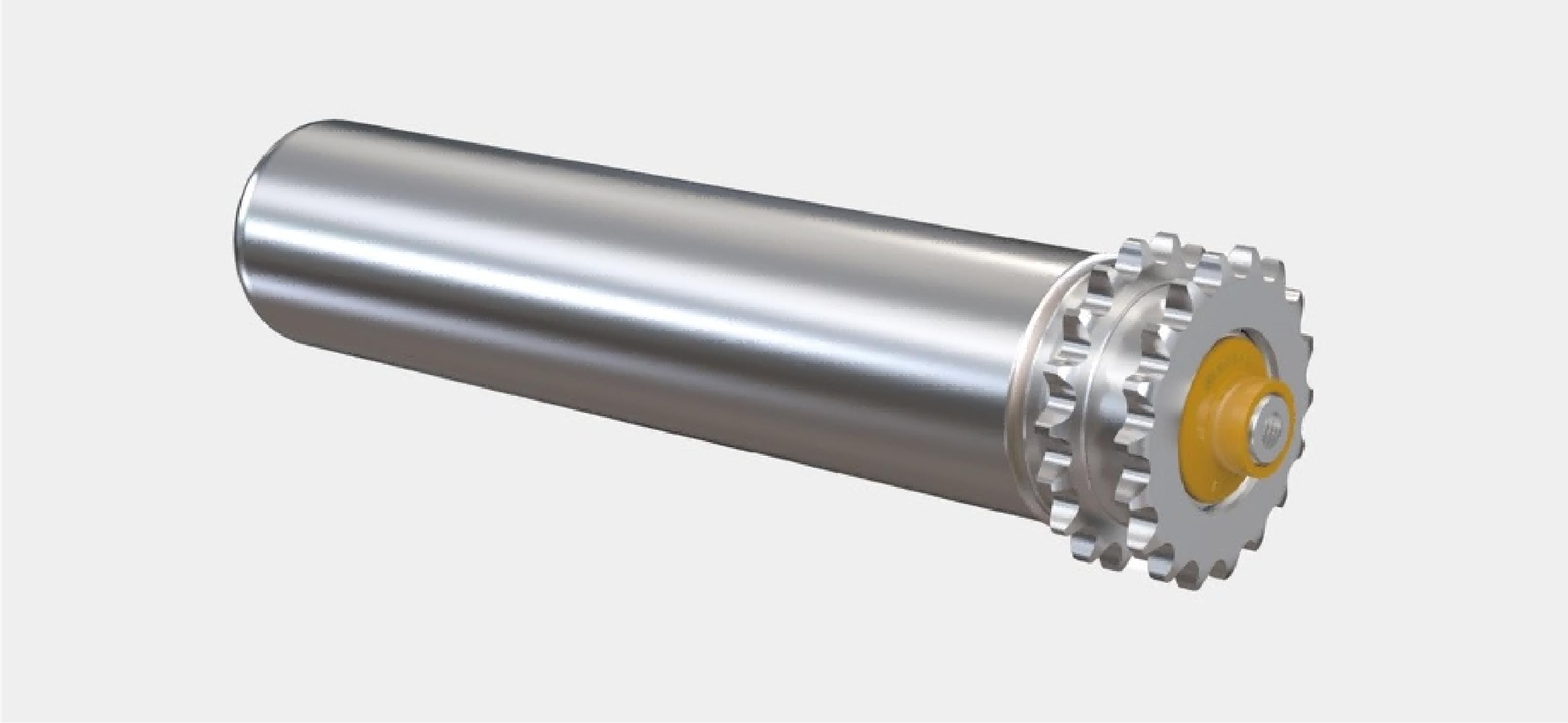

Proper operation during installation is crucial and is the primary step in preventing belt slippage:

- Proper tensioning: Adjusting the tension between the drum motor and the conveyor belt to ensure that the belt does not slip under load while avoiding excessive tension.

- Sufficient width coverage: Ensuring that the width of the conveyor belt covers more than 2/3 of the width of the drum motor body to provide sufficient contact area and reduce the risk of slippage.

- Parallel installation: Keeping the drum motor parallel to the driven roller to avoid misalignment during operation.

Apologies for the confusion. Let me provide the translations with the numbering unchanged:

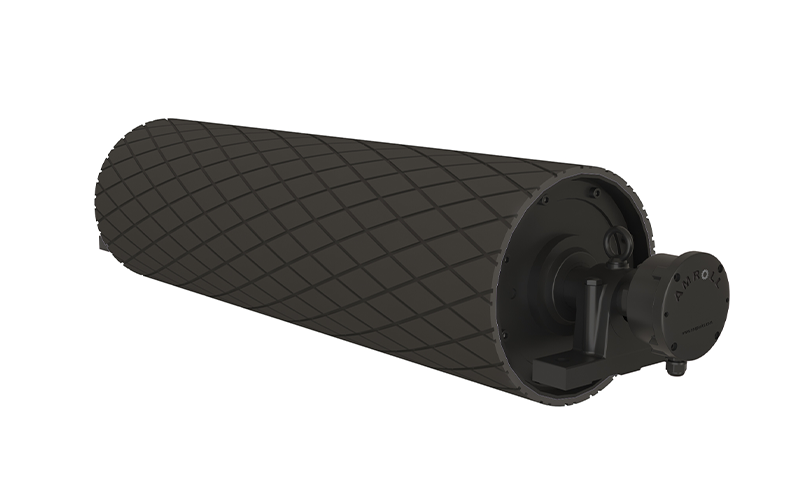

3. **Selection of Belt Material:**

Choosing the appropriate belt material based on the working environment and nature of the conveyed materials is fundamental to preventing slippage:

- Suitable material selection: For special environments such as high temperature, abrasion, and chemical corrosion, choose rubber belts that can withstand these factors.

- Regular belt replacement: Periodically inspect belt wear and promptly replace severely worn belts to ensure the normal operation of the drum motor.

4. **Adjustment of Tensioning Force:**

Proper tensioning force is one of the key factors in preventing belt slippage:

- Regular inspection of tensioning devices: Periodically check tensioning devices to ensure they are functioning properly and providing the appropriate tension to the belt.

- Adjustment of appropriate tensioning force: Regularly adjust the tensioning force based on actual usage to maintain proper contact between the belt and the drum motor.

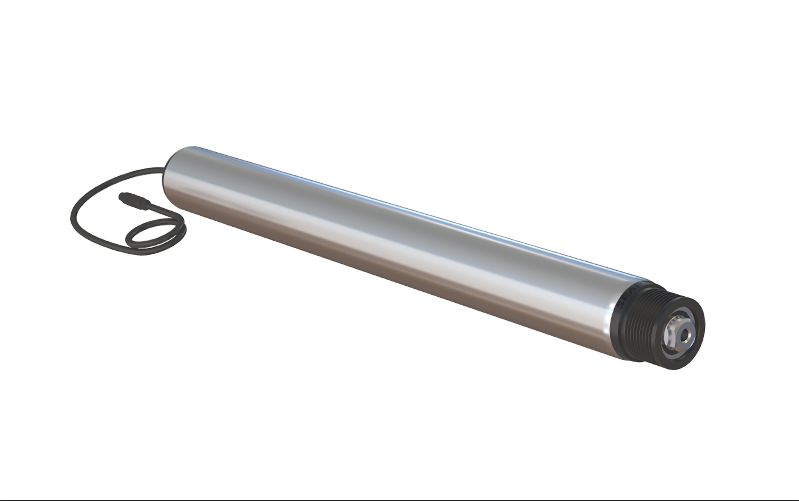

5. **Control of Drum Motor Speed:**

Proper drum motor speed is crucial in preventing slippage issues:

- Reasonable drum motor speed: Adjust the drum motor speed according to the nature of the conveyed materials and the belt material to avoid slippage caused by excessive speed or slow speed.

- Real-time monitoring of belt status: Continuously monitor the belt operation status and promptly adjust the position of the drum motor if misalignment is detected to prevent belt slippage.

6. **Control of Material Properties:**

Effectively controlling the temperature and granularity of conveyed materials is crucial in preventing slippage:

- Appropriate temperature control: Ensure the surface temperature of the belt is suitable for high-temperature materials to prevent belt slippage caused by overheating.

- Suitable granularity: For materials with larger particle sizes, select appropriate conveying equipment and belts to avoid particle wear on the belt, thus reducing the risk of slippage.

7. **Maintenance Strategies:**

Regular maintenance is one of the key measures to prevent belt slippage of drum motors:

- Regular cleaning of belt surface: Remove oil stains, dust, and other debris to keep the belt surface clean.

- Inspection of belt tension: Periodically check the tension of the belt to ensure proper contact between the belt and the drum motor.

- Inspection of drum surface: Regularly inspect the drum surface, and promptly repair or replace it in case of wear or rust issues.

By adhering to the above precautions, you will be able to effectively prevent belt slippage of drum motors. This not only enhances production line efficiency but also prolongs the lifespan of the equipment. If you have any questions or need guidance, please feel free to contact our professional team.