Motor type: Asychronous, AC, 1&3 Phase

Key words:Belt drive, Oli-filled

Tag:Light-duty, Silent

AMROLL Drum Motor TM80A-1*230V/50Hz |

|||||||||

| Power [kW/hp] |

No.of poles |

Gear stages |

Gear ratio |

Nominal belt speed [m/s] |

Full load torque [Nm] |

Full load belt pull [N] |

Full load current [A] |

Min. face width (L) [mm] |

Min.L Weight [kg] |

|

0.034/0.045 |

4 |

3 |

74.79 |

0.08 |

16.41 |

400 |

0.48 |

350 |

6.5 |

|

55.11 |

0.10 |

13.11 |

320 |

||||||

|

37.89 |

0.15 |

8.73 |

214 |

||||||

|

2 |

28.95 |

0.20 |

6.55 |

160 |

|||||

|

21.33 |

0.27 |

4.85 |

118 |

||||||

|

14.67 |

0.40 |

3.28 |

80 |

||||||

|

11.81 |

0.50 |

2.62 |

64 |

||||||

|

0.06/0.08 |

2 |

3 |

74.79 |

0.15 |

15.42 |

391 |

0.57 |

350 |

6.5 |

|

55.11 |

0.20 |

11.01 |

269 |

||||||

|

37.89 |

0.30 |

7.71 |

188 |

||||||

|

2 |

28.95 |

0.39 |

5.91 |

142 |

|||||

|

21.33 |

0.52 |

4.37 |

104 |

||||||

|

14.67 |

0.76 |

2.95 |

71 |

||||||

|

11.81 |

0.95 |

2.36 |

56 |

||||||

|

0.085/0.115 |

2 |

3 |

74.79 |

0.16 |

19.28 |

489 |

0.66 |

350 |

6.5 |

|

55.11 |

0.22 |

13.77 |

336 |

||||||

|

37.89 |

0.32 |

9.63 |

236 |

||||||

|

2 |

28.95 |

0.41 |

7.38 |

177 |

|||||

|

21.33 |

0.56 |

5.46 |

131 |

||||||

|

14.67 |

0.81 |

3.69 |

89 |

||||||

|

11.81 |

1.01 |

2.96 |

71 |

||||||

|

0.11/0.15 |

2 |

3 |

55.11 |

0.22 |

22.02 |

538 |

0.99 |

350 |

6.5 |

|

37.89 |

0.32 |

15.42 |

376 |

||||||

|

2 |

28.95 |

0.42 |

11.82 |

284 |

|||||

|

21.33 |

0.56 |

8.74 |

208 |

||||||

|

14.67 |

0.82 |

5.90 |

142 |

||||||

|

11.81 |

1.02 |

4.72 |

112 |

||||||

| At the min. face width (L), the total weight of a drum motor grows approx.1.2 kg per 100 mm. | |||||||||

AMROLL Drum Motor TM80A-3 *400V/50Hz |

|||||||||

|

Power [kW/hp] |

No.of poles |

Gear stages |

Gear ratio |

Nominal belt speed [m/s] |

Full load torque [Nm] |

Full load belt pull [N] |

Full load current [A] |

Min. face width (L) [mm] |

Min.L Weight [kg] |

|

0.04/0.05 |

4 |

3 |

74.79 |

0.08 |

18.00 |

450 |

0.43 |

350 |

6.7 |

|

55.11 |

0.10 |

14.40 |

360 |

||||||

|

37.89 |

0.15 |

9.60 |

240 |

||||||

|

0.06/0.08 |

2 |

3 |

74.79 |

0.15 |

19.28 |

489 |

0.30 |

330 |

6 |

|

55.11 |

0.20 |

13.77 |

336 |

||||||

|

37.89 |

0.30 |

9.63 |

236 |

||||||

|

2 |

28.95 |

0.39 |

7.38 |

177 |

|||||

|

21.33 |

0.52 |

5.46 |

131 |

||||||

|

14.67 |

0.76 |

3.69 |

89 |

||||||

|

11.81 |

0.95 |

2.96 |

71 |

||||||

|

4 |

3 |

55.11 |

0.10 |

28.91 |

705 |

0.36 |

350 |

6.7 |

|

|

37.89 |

0.15 |

19.27 |

470 |

||||||

|

0.09/0.12 |

2 |

3 |

74.79 |

0.16 |

23.13 |

587 |

0.43 |

330 |

6 |

|

55.11 |

0.22 |

16.52 |

403 |

||||||

|

37.89 |

0.32 |

11.56 |

283 |

||||||

|

2 |

28.95 |

0.41 |

8.86 |

212 |

|||||

|

21.33 |

0.56 |

6.55 |

157 |

||||||

|

14.67 |

0.82 |

4.43 |

106 |

||||||

|

11.81 |

1.01 |

3.55 |

85 |

||||||

|

0.12/0.16 |

2 |

3 |

55.11 |

0.22 |

22.02 |

538 |

0.53 |

330 |

6 |

|

37.89 |

0.32 |

15.42 |

376 |

||||||

|

2 |

28.95 |

0.42 |

11.82 |

284 |

|||||

|

21.33 |

0.56 |

8.74 |

208 |

||||||

|

14.67 |

0.82 |

5.90 |

142 |

||||||

|

11.81 |

1.02 |

4.72 |

112 |

||||||

| At the min. face width (L), the total weight of a drum motor grows approx.1.2 kg per 100 mm. | |||||||||

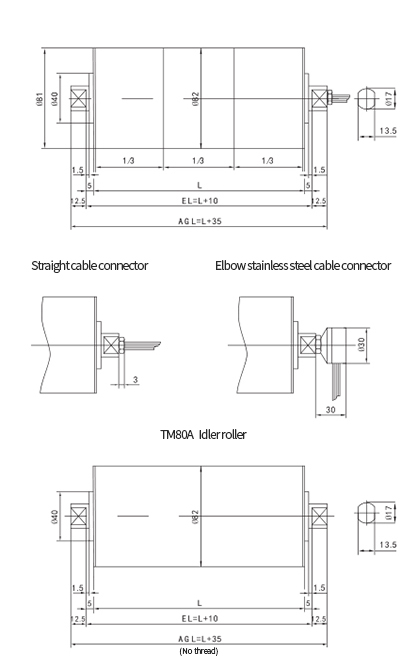

TM80A optional list-drum motor/idler pulley |

||

|

Specifications |

Drum motor |

Idler pulley |

|

Shell |

|

|

|

Mild steel crowned |

1 |

1 |

|

Mild steel cylindrical |

2 |

2 |

|

Stainless steel(std. 304) crowned |

2 |

2 |

|

Stainless steel(std. 304) cylindrical |

2 |

2 |

|

End housing (front & rear) |

|

|

|

Cast aluminium |

1 |

1 |

|

Shaft (front & rear) |

|

|

|

Mild steel |

1 |

1 |

|

Stainless steel(std. 304) |

2 |

2 |

|

Gear box & rear flange |

|

|

|

Cast aluminium |

1 |

1 |

|

Electrical motors |

|

|

|

1 or 3-phase asynchronous motor |

1 |

|

|

Voltage 1*230V/50Hz or 3*400v/50Hz |

1 |

|

|

Most common global voltages at 50 or 60 Hz |

1 |

|

|

Thermal protection |

1 |

|

|

Lubricating oil |

|

|

|

No.150 gear oil |

1 |

|

|

Low temperature oil |

2 |

|

|

Food grade oil & grease (FDA and USDA) |

2 |

|

|

Electrical connection |

|

|

|

Straight cable connector |

1 |

|

|

Elbow stainless steel cable connector |

2 |

|

|

Oil resistant PVC cable |

1 |

|

|

LS halogen-free cable |

2 |

|

|

Other options |

|

|

|

Mechanical backstop |

2 |

|

|

Note:1-fitted as standard 2-optional extras |

||